June 2005 – June 2009: Smoothing Boundary Curves. ESPRC GR/T24579/01. PI: R. R. Martin, CoI: F. C. Langbein. Industrial partner: Delcam Int PLC. £196.722.

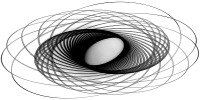

Computer aided design and manufacturing use boundary curves derived from surfaces for many tasks such as machining, mould and die design, and reverse engineering. Both the nature of the input data, and numerical errors, can lead to computed boundary curves which lack sufficient smoothness for such processes. This work aims to devise novel mathematical methods and algorithms for smoothing boundary curves. These curves may lie on the surface, like a boundary delimiting two halves of a mould for moulding a plastic object, or they may be offset from the surface, e.g. delimiting a no-go area whilst machining the object. The smoothed boundary curves should meet various constraints, e.g. they must be sufficiently close to the input curve and surface, and they must eliminate kinks and doubling back. Other constraints depend on the application e.g. the smoothed boundary curve must not lie anywhere within the input curve for no-go boundaries. We aim to devise novel methods which will smooth boundary curves derived both from surfaces represented as triangle meshes, and represented mathematically using B-splines. A subsidiary objective is to adjust the input surfaces to conform to the smoothed boundary curve.This research will be carried out in cooperation between the School of Computer Science at Cardiff University, and Delcam plc, Birmingham.

![]() This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.