W. Li, R. R. Martin, F. C. Langbein. Merging and Smoothing Machining Boundaries on Cutter Location Surfaces. In: Proc. ACM Symp. Solid and Physical Modeling, pp. 165-170, 2010. [DOI:10.1145/1839778.1839803] [PDF]

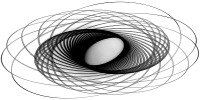

In region machining, neighbouring regions may be close together, but disconnected. Boundary curves may also have unwanted geometric artifacts caused by approximation and discretisation. We present a strategy to improve the topology and geometry of such boundary curves, allowing the generation of better tool paths, and in turn, improved tool wear and surface quality of the machined part. We make such improvements in three steps: firstly, disconnected regions are merged where appropriate, using a method based on morphological operations from image processing. Secondly, boundary segments with undesirable geometric properties are identified and replaced by simpler segments, using a vertex deletion operation. Finally, flaws at a smaller geometric scale are removed, using a curve shortening algorithm. Experimental results are given to illustrate our algorithm.

![]() This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.