B. I. Mills, F. C. Langbein, A. D. Marshall, R. R. Martin. Estimate of Frequencies of Geometric Regularities for Use in Reverse Engineering of Simple Mechanical Components. Technical Report GVG 2001-1, Computational Geometry and Computer Vision Group, Dept. Computer Science, Cardiff University, 2001. [DOI:10.13140/RG.2.1.3683.2087] [PDF]

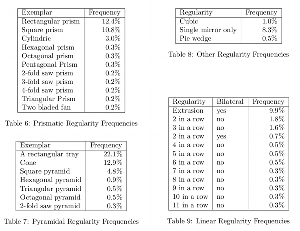

The authors are investigating reverse engineering for reconstructing the shape of simple mechanical parts. Currently, preliminary B-rep models can be created by fitting surfaces to point clouds obtained by scanning an actual part using a 3D laser scanner. The resulting model, although valid, is often not suitable for purposes such as redesign. This is because expected regularities and constraints are not present in the model. This report describes a number of aspects of the geometry of mechanical parts which should be exploited to adjust a B-rep model to improve its usefulness. Aspects considered are geometric constraints between surface parameters, regularly repeated substructures, symmetry, and the presence of features such as slots and holes. The results of a survey of a range of mechanical parts are presented and discussed, showing which of these aspects occur with a frequency that justifies their use in beautification algorithms intended to turn preliminary reverse engineered B-rep models into models engineers expect.

![]() This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.